Loading dock Dock to ground ramps Container forklift ramps Container loading ramp

Classification :

Keywords:

Dock Leveler

Loading and unloading aids:

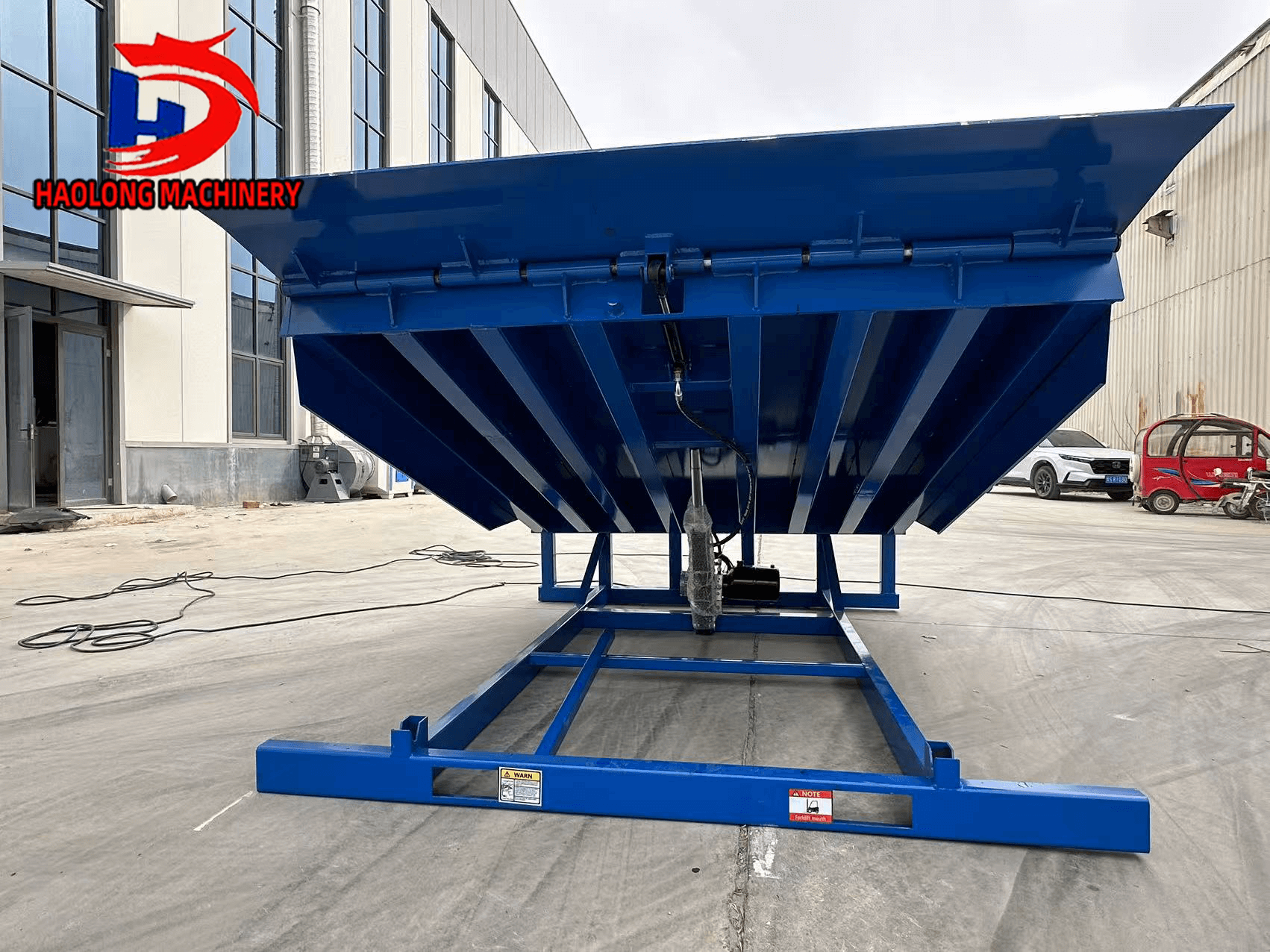

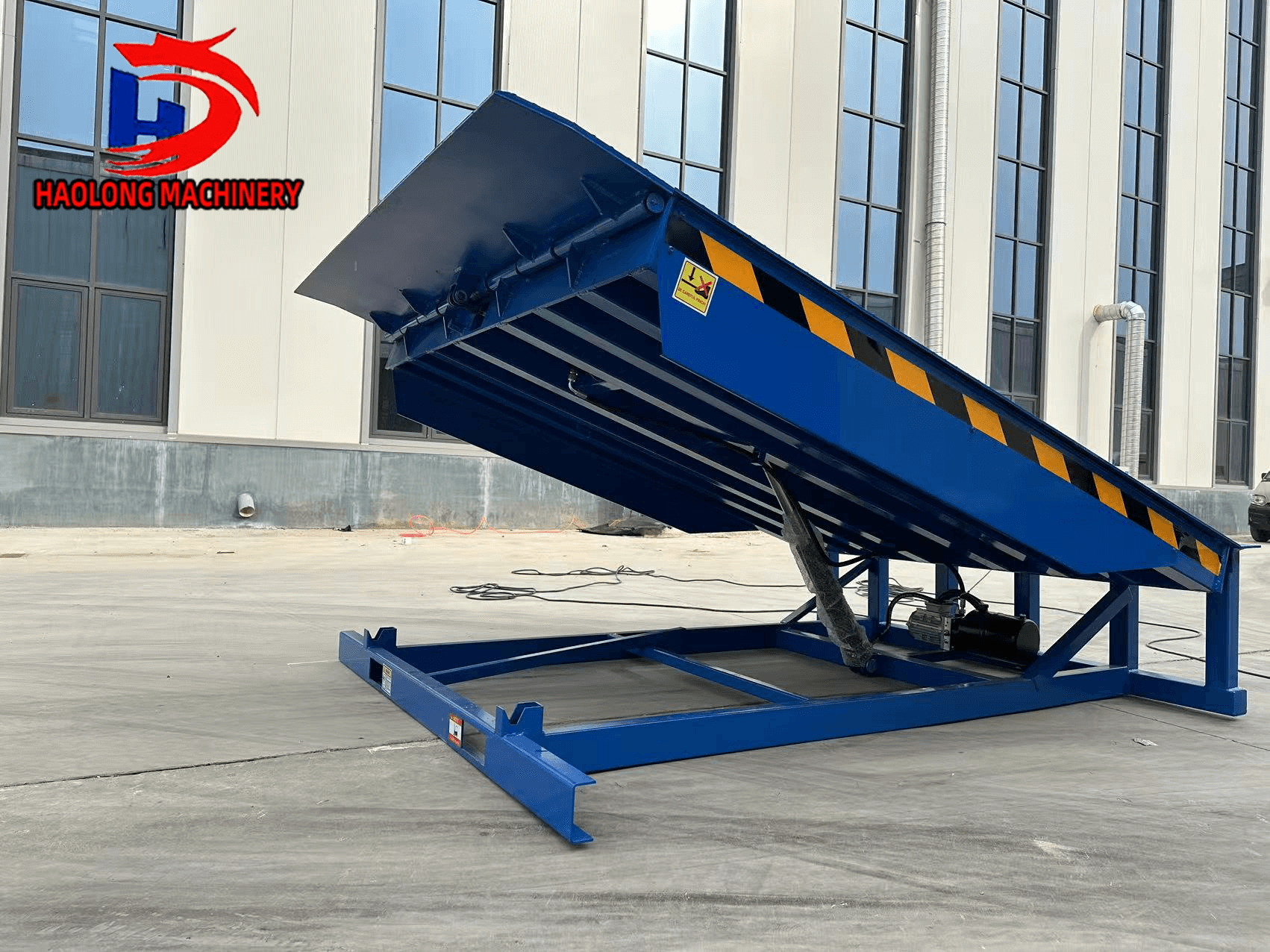

The fixed boarding bridge is the loading and unloading auxiliary equipment together with the storage platform, the equipment is integrated with the platform, and can be adjusted high or low according to the different height adjustment of the truck compartment, which is convenient for the forklift to enter the carriage, and the equipment adopts imported hydraulic pump station, and the two sides are equipped with anti-rolling skirts, which makes the work safer and improves work efficiency.

Introduction to fixed boarding bridges:

The fixed boarding bridge serves as specialized auxiliary equipment for achieving rapid goods loading and unloading, particularly critical for container forklift ramps and container loading ramps. Leveraging its height-adjustment function, it establishes a seamless bridge between the truck’s freight platform—including container trucks—and the warehouse, enabling forklifts to directly enter the truck or container for batch loading/unloading operations. With single-person operation, it eliminates the need for excessive labor, streamlining workflows for loading dock environments managed by loading dock suppliers or manufacturers.

Designed through meticulous forklift ramp design principles, the fixed boarding bridge incorporates a robust, fully hydraulic drive system, ensuring reliable performance across diverse loading dock manufacturing standards. Its high-strength "U"-shaped beam structure and anti-slip pattern steel plates are engineered to withstand heavy loads from container logistics, making it a cornerstone for loading docks handling regular container traffic.

By minimizing manual labor and accelerating cargo turnover—especially for containerized goods—this equipment helps enterprises optimize logistics processes managed by loading dock suppliers, boost productivity, and secure greater economic returns. As a key component in modern warehouse and logistics infrastructure, the fixed boarding bridge exemplifies how advanced forklift ramp design and loading dock manufacturing can enhance efficiency in high-volume container loading/unloading scenarios.

Performance:

Fully hydraulically driven, easy to operate and reliable to operate. The lip plate and the platform are connected by a whole long axis, which has high strength and good reliability. Imported seals are used to ensure that the hydraulic system has excellent sealing performance. It adopts imported integral modular hydraulic station, which has good sealing and long service life. The high-strength "U" beam design can ensure that it will not deform for a long time under high loads. The anti-skid pattern steel plate is used to make the platform have good anti-skid performance. The two sides are equipped with anti-rolling skirt plates to prevent the toes from sticking into the platform and causing accidental injury. There is a support rod to ensure the safety of maintenance personnel when entering the boarding bridge for maintenance.

Introduction:

The fixed boarding bridge, also known as the platform lift (height adjustment board), can easily and flexibly connect the front end of the unloading platform with the truck through electric control, so that the loading and unloading vehicles and personnel can enter and exit the truck directly in parallel and unhindered to load and unload goods, and greatly improve the loading and unloading efficiency

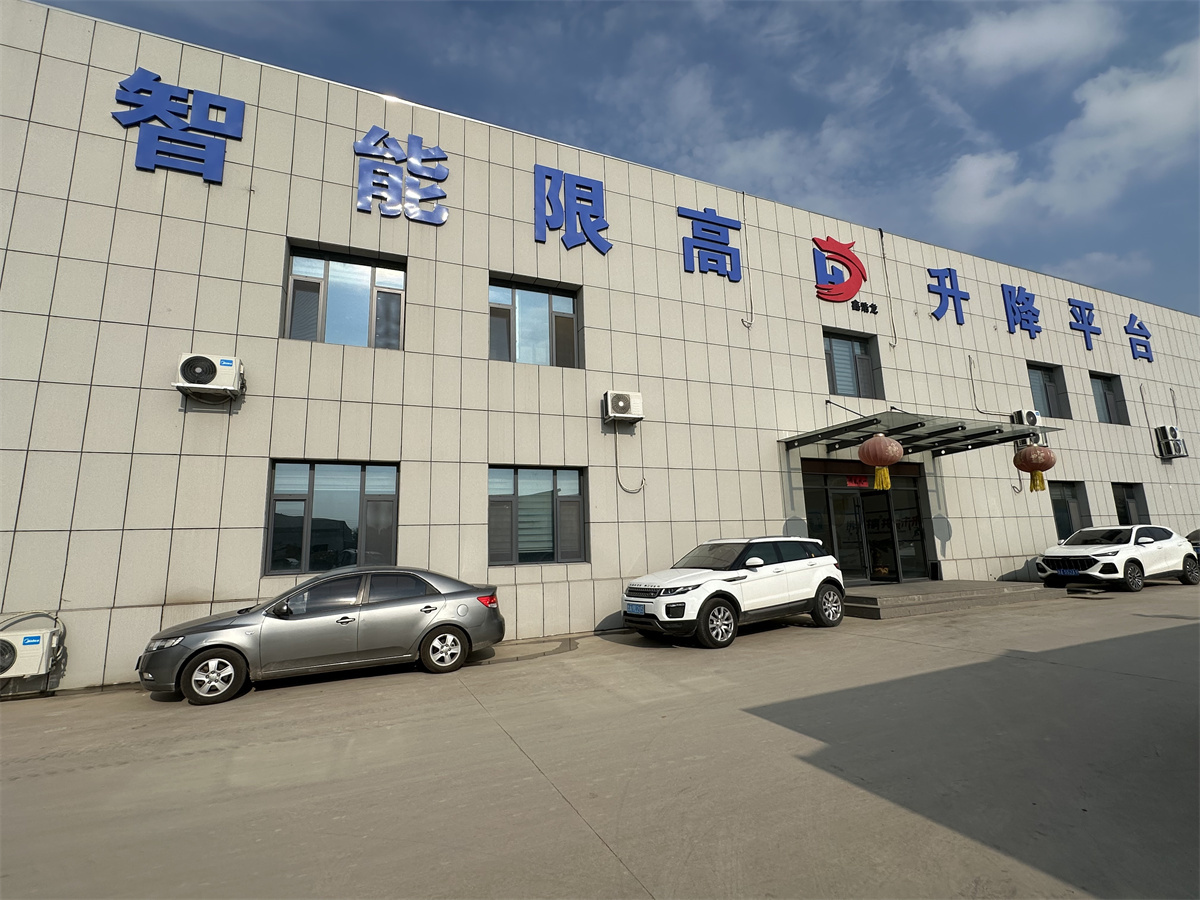

Brand factory display:

|

|

|

|

|

|

|

|

|

FAQ

RELATED PRODUCTS

GET A FREE QUOTE