Dock to ground ramps Container forklift ramps Container loading ramps Loading dock manufacturing Forklift ramp design

Classification :

Keywords:

Dock Leveler

Loading and unloading aids:

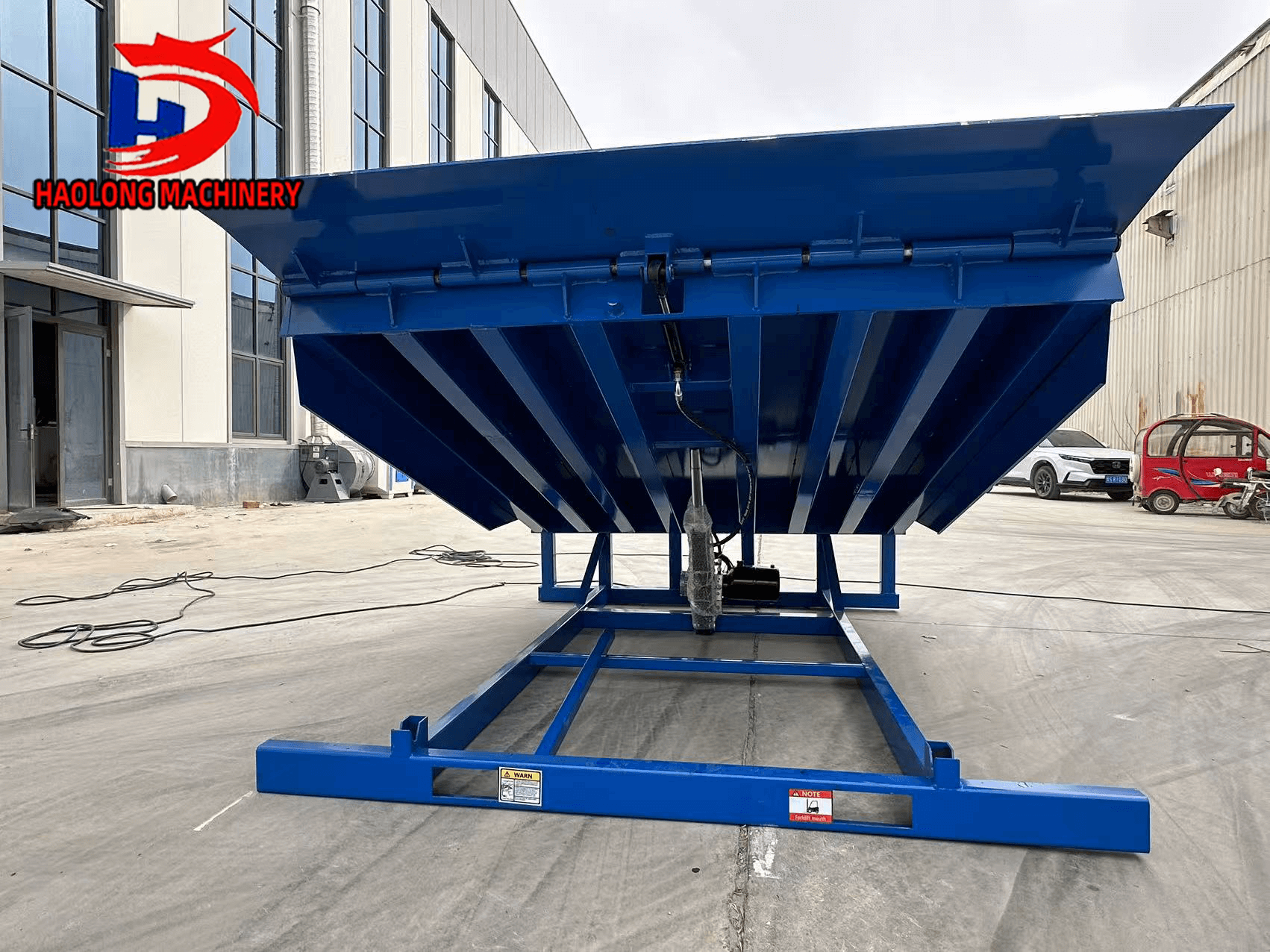

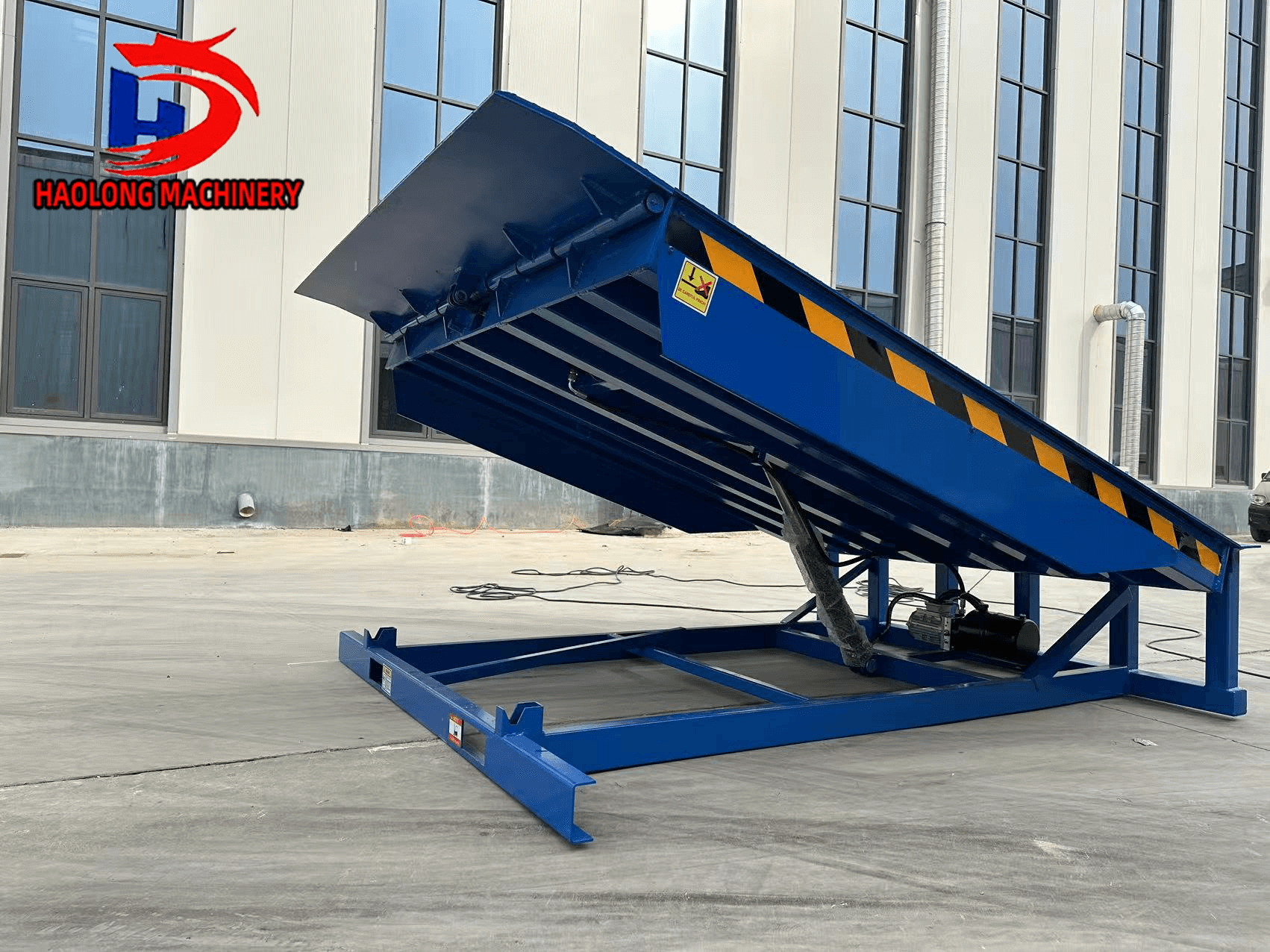

The fixed boarding bridge is the loading and unloading auxiliary equipment together with the storage platform, the equipment is integrated with the platform, and can be adjusted high or low according to the different height adjustment of the truck compartment, which is convenient for the forklift to enter the carriage, and the equipment adopts imported hydraulic pump station, and the two sides are equipped with anti-rolling skirts, which makes the work safer and improves work efficiency.

Introduction to fixed boarding bridges:

Hydraulic dock levelers and manual loading dock levelers are the mainstays for adjusting the height difference between the loading dock platform and truck carriages. The former uses a hydraulic system for precise lifting, while the latter, operated manually, is suitable for low-frequency scenarios. Professional dock leveler installation ensures their stable operation. The telescopic dock leveler, as an innovative device, further optimizes the docking process through its telescopic function. It works in tandem with the dock leveler system to enhance efficiency. The renowned brand Blue Giant Dock Leveler is highly favored for its reliable quality.

Performance:

Among ramp equipment, truck ramps, dock to ground ramps, and ramps for containers create passages between the ground and transportation vehicles. Mobile dock ramps offer great flexibility with no need for fixed installation, making them ideal for temporary loading and unloading. Forklift ramps for containers are specifically designed for forklifts, ensuring the safe handling of containerized goods. Container loading ramps, shipping container ramps, and container ramps are tailored for container loading and unloading, and there are numerous container ramps for sale on the market. Additionally, loading dock plates and dock boards are lightweight and portable, commonly used for the temporary handling of small goods, and there is a wide selection of dock plates for sale.

Introduction:

For equipment procurement needs, you can contact professional dock leveler suppliers. They not only provide equipment such as load platforms and hydraulic loading platforms but also offer customized forklift ramp designs and dock leveler designs according to requirements. Dock leveler manufacturing companies are constantly innovating, researching, and developing more efficient loading dock equipment in ramp yards, driving the development of the industry forward.

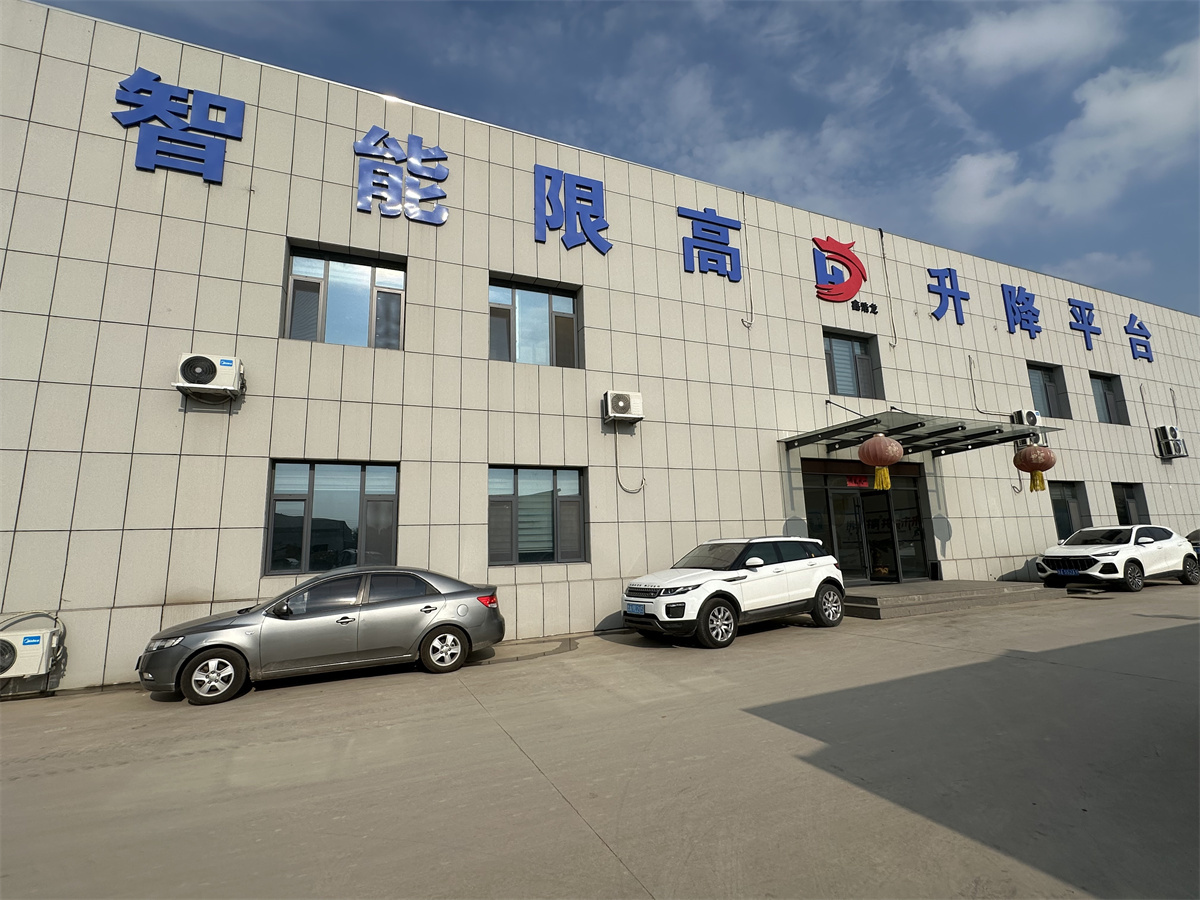

Brand factory display:

|

|

|

|

|

|

|

|

|

FAQ

RELATED PRODUCTS

GET A FREE QUOTE