ramp for container dock leveler system hydraulic lift ramp manual loading dock leveler

Classification :

Keywords:

Dock Leveler

Definition and purpose:

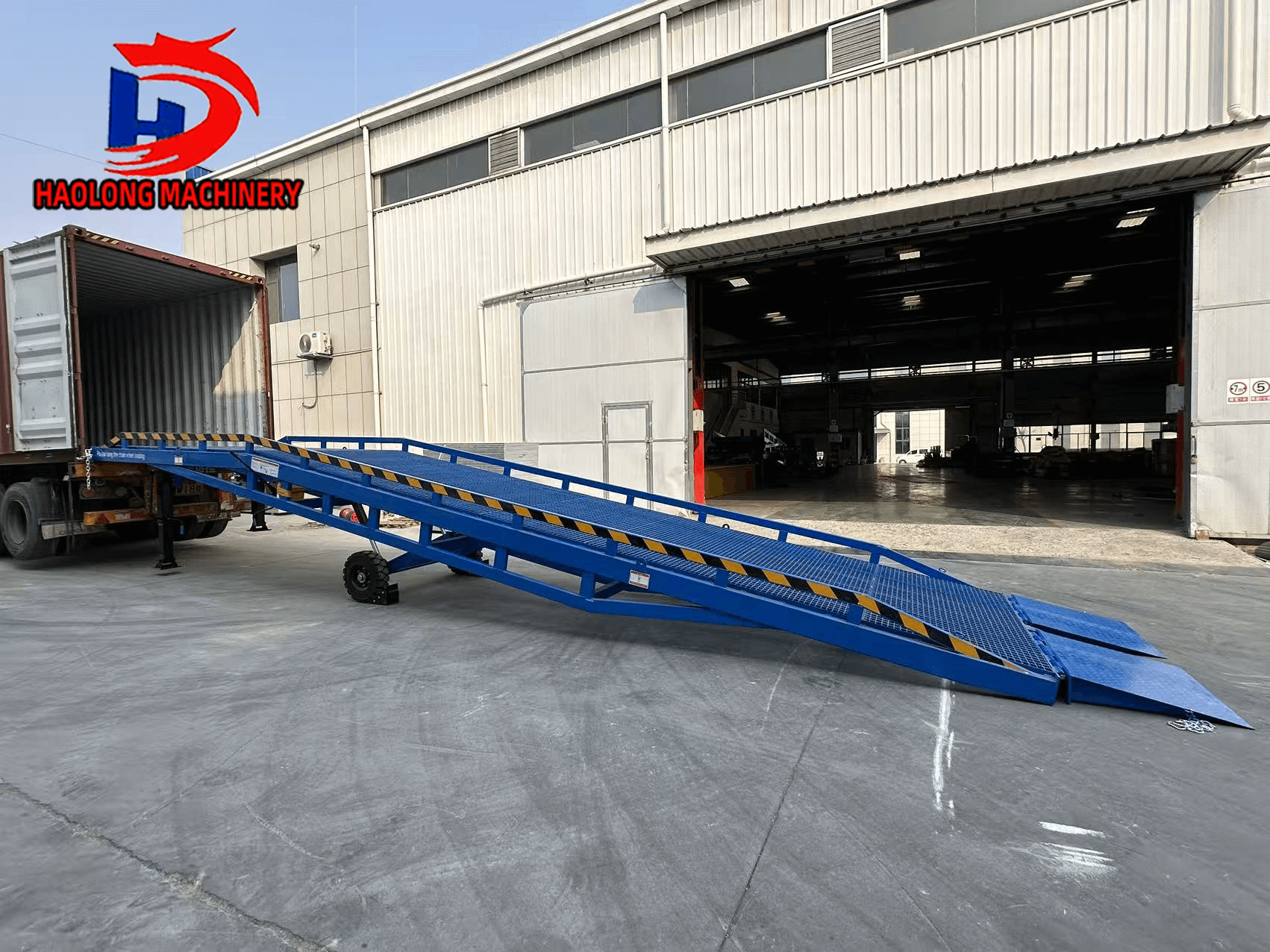

The forklift loading and unloading ramp is a special auxiliary equipment for rapid loading and unloading of goods. Its height adjustment function allows a ramp bridge to be built between the truck and the warehouse and the container platform. Through it, forklifts and other transportation vehicles can directly drive into the truck for loading and unloading, enabling batch loading and unloading of goods to achieve rapid loading and unloading work.

Among the various types of ramps, the 10 ton forklift ramp stands out for its robust design, capable of handling heavy - duty loads. For container - centric operations, the load ramp container and hydraul load ramp are indispensable. The load ramp container is specifically tailored for seamless interaction with shipping containers, while the hydraul load ramp, with its hydraulic mechanism, ensures smooth and stable loading and unloading processes.

The hydraul ramp, known for its efficient hydraulic system, provides enhanced maneuverability and height adjustment capabilities. When it comes to dock - related operations, the load dock lift and dock movabl ramp play crucial roles. The load dock lift facilitates the vertical movement of goods, bridging the height gap between the dock and the vehicle, and the dock movabl ramp offers flexibility, as it can be easily relocated to different docking positions.

The Movable boarding bridge hydraulic unloading lifting platform, available in capacities of 8/10/15/20 tons, is a prime example of these versatile loading and unloading solutions. It can be customized according to the usage. Only one person is required to operate, and no power source is needed to achieve safe and rapid loading and unloading of goods.

Classification:

Boarding bridges are mainly divided into movable boarding bridges and fixed boarding bridges. The mobile boarding bridge can adjust the height according to the height of the car compartment, and the forklift can directly drive into the compartment through this equipment for batch loading and unloading of goods. The fixed boarding bridge is mainly used to build a bridge between the cargo platform and the transport vehicle, so that transport vehicles such as forklifts can directly drive into the truck for loading and unloading operations.

Structure and working principle:

Mobile ramps (a type of mobile ramp and mobile yard ramp) feature a diamond mesh or steel grating structure with special diamond grating plates and hollow steel grating materials. Its design includes the tailgate, ramp hydraulics, cylinders and tires, and is reinforced with ribs to ensure reliable strength and anti-skid performance. This makes it ideal for scenarios such as container loading ramps or container ramps, which enable direct access between containers and the ground or between containers and warehouses.

For fixed infrastructure, the fixed ramp is a fully hydraulically driven hydraulic ramp that is easy to operate and reliable. It features a high-strength torque tube design and anti-skid mesh, which is essential for heavy-duty applications such as container ramps and mobile loading ramps.

Other solutions include mobile ramps that match the portability of mobile ramps, and ramp loading and unloading services that ensure seamless integration with warehouse terminals. All models, whether mobile or fixed, prioritize safety and efficiency in loading and unloading workflows, from container ramp operations to general truck logistics.

Usage scenarios:

In the bustling realm of logistics and warehousing, a diverse array of equipment plays a pivotal role in streamlining cargo handling operations. Hydraulic ramps, load ramp containers, and hydraulic load ramps, leveraging hydraulic technology, offer seamless height adjustment, enabling effortless alignment with trucks, trailers, and other transport vehicles, thus ensuring smooth cargo transitions. Load dock lifts, 10-ton forklift ramps, 20-ton container low ramps, and load forklift ramps serve as sturdy workhorses, providing the necessary support and stability for the movement of heavy loads, whether it’s bulky machinery or dense containerized goods.

The new hydraulic lifting ramps for warehouses, load dock containers, and load dock platforms enhance the functionality of storage facilities, optimizing space utilization and facilitating quick, efficient loading and unloading within the warehouse environment. Mobile dock ramps and ramp pairs for forklifts bring flexibility to the forefront, allowing for easy relocation and adaptation to various loading scenarios, which is especially beneficial in dynamic logistics hubs.

In the UAE, container loading ramps have been tailored to meet the region’s high-volume shipping demands, ensuring rapid turnaround times for containers. Completing the ecosystem, loading dock plates, truck ramps, dock boards, and hydraulic dock levelers act as the final links, creating a continuous and level surface between the dock and the vehicle. This seamless integration of equipment not only boosts operational efficiency but also minimizes the risk of damage to goods and injuries to workers, making them indispensable assets in the modern logistics industry.

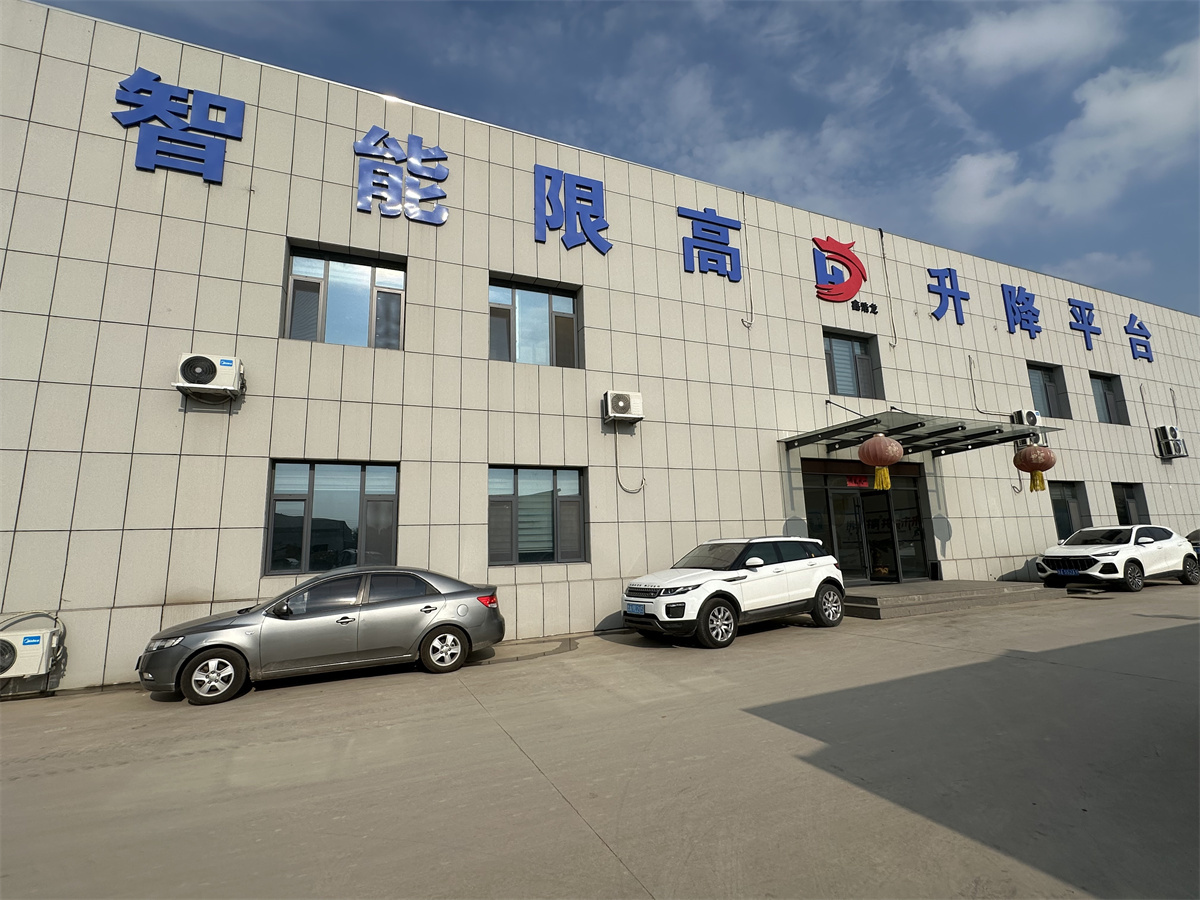

Brand factory display:

|

|

|

|

|

|

|

|

|

FAQ

RELATED PRODUCTS

GET A FREE QUOTE