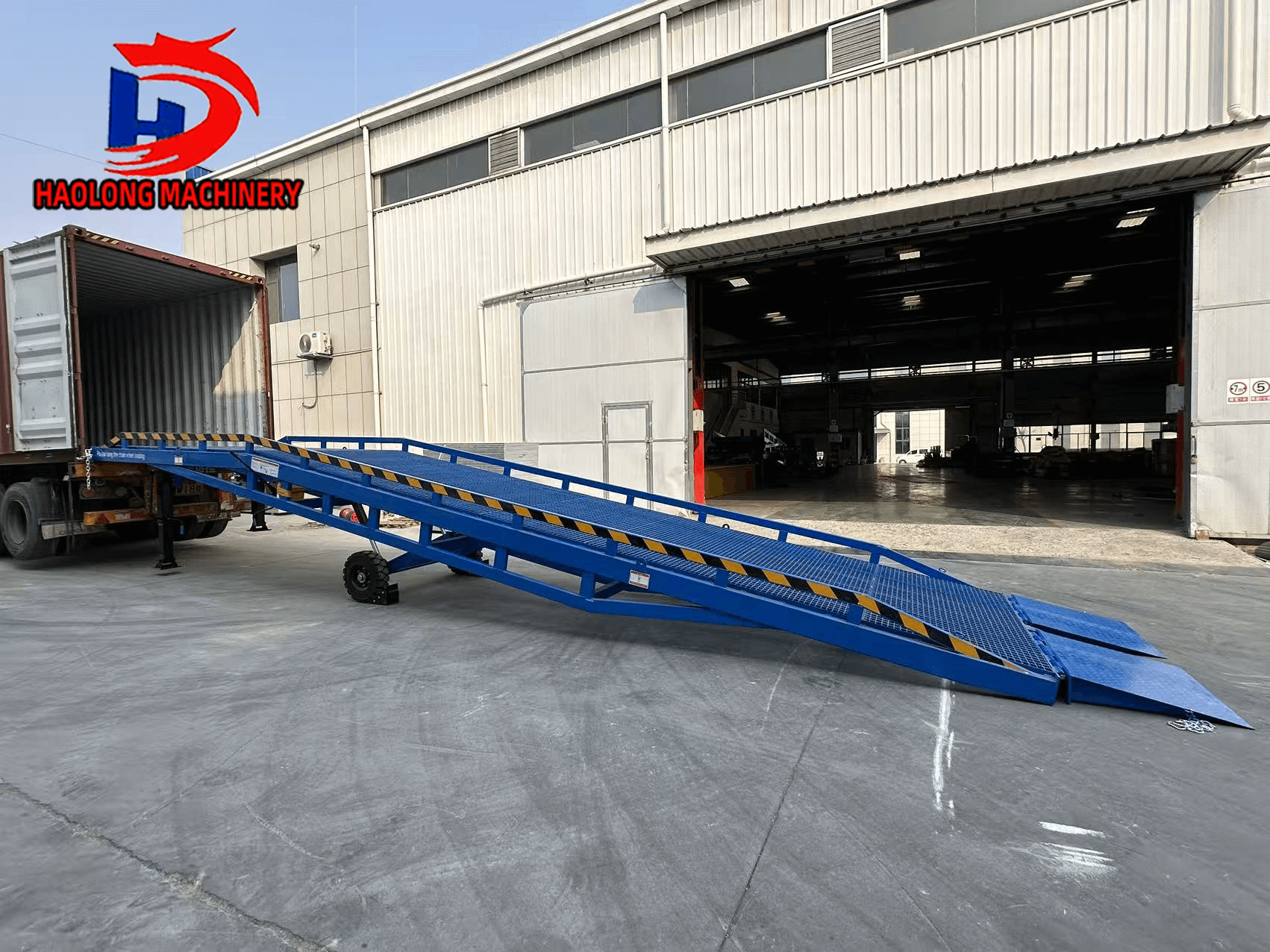

shipping container ramp mobile loading dock ramp dock leveler manufacturing forklift ramp design

Classification :

Keywords:

Dock Leveler

Definition and purpose:

Loading Dock Equipment: The Core Support for Efficient Logistics

In modern logistics and warehousing industries, loading dock equipment is pivotal for ensuring the efficient flow of goods. From basic devices like loading dock plates, truck ramps, and dock boards to sophisticated hydraulic dock levelers, these various pieces of equipment together form a complete loading and unloading system.

Loading dock plates and dock boards quickly bridge trucks and loading platforms, facilitating cargo handling. Truck ramps, conversely, offer flexible access in scenarios lacking fixed loading docks. Hydraulic dock levelers, with their hydraulic lifting function, can adapt to different truck bed heights, significantly boosting loading and unloading efficiency, thus gaining favor among large logistics centers.

Classification:

Mobile ramps and other mobile loading and unloading equipment stand out for their flexibility. Requiring no fixed installation, they are ideal for temporary or space - constrained areas. Container loading ramps, designed specifically for container handling, paired with forklift ramps for containers, resolve the challenges of loading and unloading containerized goods.

The installation and manufacturing of loading dock equipment are equally crucial. Dock leveler installation demands professional teams to ensure precision and safety, while every stage of dock leveler manufacturing, from design to production, impacts equipment performance. Specialized products such as telescopic dock levelers meet diverse market needs.

Structure and working principle:

Ramps and loading and unloading pads are light and easy to operate. They are often used for temporary handling of small goods. Although they have limited load capacity, they are affordable and easy to store. They are cost-effective choices for places with small traffic.

From loading and unloading docks to truck unloading docks, the entire process relies on the rational planning of ramp yards and load platforms. Dock leveler suppliers not only provide equipment but also offer after - sales service and technical support. In the future, loading dock equipment will evolve towards intelligence, high efficiency, and enhanced safety, providing more robust support for logistics transportation.

Usage scenarios:

When purchasing, you can find a professional supplier to purchase hydraulic ramps and customize forklift ramp designs. Well-known brands such as Blue Giant Dock Leveler are reliable in quality, professional manufacturers can also optimize the design and provide exclusive solutions, and manual loading and unloading platforms can also meet different budget requirements. Choosing the right equipment can significantly improve logistics efficiency and reduce costs.

Brand factory display:

|

|

|

|

|

|

|

|

|

FAQ

RELATED PRODUCTS

GET A FREE QUOTE